Non-contact magnetometric diagnostics of pipelines

At present practical application of non-contact magnetometric diagnostics (NCMD) during the assessment of underground or underwater gas and oil pipelines, heat lines, water mains and other pipelines constantly grows.

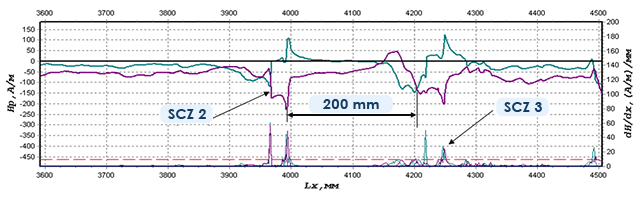

NCMD is based on measurement of distortions of the magnetic field of the Earth (HEarth), conditioned by the variation of the pipe metal's magnetic permeability in stress concentration zones (SCZs) and in zones of developing corrosion-fatigue damages. The pattern of the HEarth field variations (frequency, amplitude) is conditioned by the pipeline strain occurring in it due to the exposure to a number of factors: the residual process and installation stresses, the working load and self-compensation stresses at outdoor air and environment (soil, water, etc.) temperature fluctuation.

The criteria and the program software, developed at Energodiagnostika Co. Ltd. based on the metal magnetic memory method, are applied for decoding of the information about the pipelines condition by variations of the magnetic field of the earth recorded at the depth of 200 to 300 mm from the Earth surface.

A center for experts training in NCMD operates at Energodiagnostika Co. Ltd. Certification Body (Reutov, Moscow region). The training program incorporates the course of training in the metal magnetic memory method (8 working days) and the additional course of training in NCMD (2 working days). During the last six years more than 200 experts in NCMD from 40 diagnostic companies were trained in Russia.

In the course of experts training in NCMD Energodiagnostika Co. Ltd. Certification Body issues recommendations on the distinctive features of magnetic anomalies and diagnostic parameters that allow to distinguish maximum stress concentration zones (before the damage development) from the zone of the developing corrosion damage. The existing criteria allow to detect defected welded joints and to distinguish them from the joints in a satisfactory condition.

The main task of all diagnostic methods and means during the assessment of the condition of long-term operated gas and oil pipelines is searching (or detection) of potentially hazardous segments with developing damages. As a result of the inspection it is necessary to answer the question: "Where and when damages or accidents should be expected?" If such task is solved, it provides the possibility of timely replacement or repairs of the potentially hazardous segment. Application of NCMD in combination with the additional pipelines inspection (UT, eddy-current, etc.) in prospect holes, determined by NCMD, is aimed at exactly this task solution.

About 300 thousand kilometers of various process purpose pipelines are operated in Russia. The service life of the majority of pipelines has reached 30 years and longer. The diagnostics of pipelines' condition using in-pipe flaw detectors, which has its own drawbacks, nowadays, covers the minor part of the total pipeline length. Besides, the major part of the pipelines is not designed for passing of in-pipe flaw detectors.

Soil opening to assess the pipelines' condition along their total length, especially in urban conditions, seems to be a complicated and costly operation. As the practice shows, selective prospecting "at random" (for example, every 500 meters as per recommendation of the instructions) is low efficient without assessment of the pipelines' actual stress-strain state. In addition, such selective inspection ensures assessment of only 2-3% of the total pipeline length.

Appearance of the metal magnetic memory method in the 90-s of the last century and its recognition at the level of national and international standards as well as the development of non-contact magnetometric diagnostics based on it in the late 90-s and early 2000-created a unique possibility to solve the problem of state assessment of long pipelines operated on the Russian territory. The considered NCMD technology, born in Russia, is becoming more common in other countries as well. For example, every year Energodiagnostika Co. Ltd. experts perform contract works on pipelines NCMD in Poland, Czech Republic, Argentina, China and other countries.

There is a standard of the Moscow Heat Distribution Company (JSC "MTC") on assessment of heat lines condition using NCMD. The technique for heat lines inspection by the non-contact magnetometric method was developed in 2009 by Energodiagnostika Co. Ltd. experts under the Contract with JSC "MTC". Every year diagnostic companies perform the inspection of several hundreds of kilometers of the Moscow heat distribution system heat lines using this technique and the appropriate instrument complexes.

Measuring complex and non-contact magnetometric diagnostics in different conditions