Diagnostics of water turbine wheels and load-carrying structure at hydroelectric power station

There is an experience of usage of MMM with the purpose of early diagnostics of fatigue failures of blades of water turbine wheels.

Fig.1 shows the graph of distribution of residual magnetization field Нр registered along an output edge and in zones of coupling a rim and hub with the blade №11 of wheel of water turbine RO 230/833-В-677 G/A №6 at Sayano-Shushenskaya hydroelectric power station.

Fig.2 shows the Нр distribution directly on an output edge of same blade. From fig.2 it is seen that in zones of coupling with a lower rim the field Нр is variable-polarity and discontinuous.

Fig.3 shows the location of stress concentration lines (SC lines) detected on the blade №11 at comprehensive testing. The lines of sign change of the measuring magnetic field Нр (A/m) characterize the SC lines according to the technique. Fatigue cracks is developing at operational process along these lines.

The offered diagnostic method allows:

- to carry out an express control of blades and to estimate their predisposition to damages;

- to estimate efficiency of different actions on support of rotor reliability, in particular, efficiency of different technologies of repair (control of welding of flaws, control of a clod-hardening etc.). At a control of weld joints MMM allows to reveal stress concentration in local zones and in time to strengthen these zones.

Diagnostics of load-carrying structure at hydroelectric power station

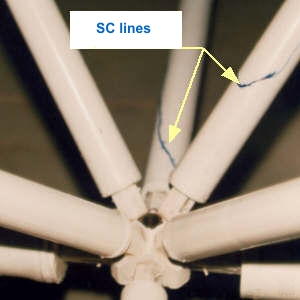

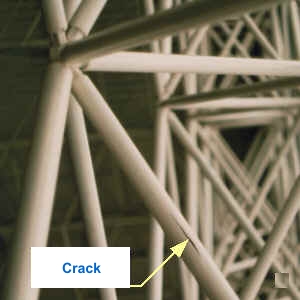

Photo 1 shows the location of SC lines on bars of the space-framed structure MARHI of the powerhouse hall at Sayano-Shushenskaya hydroelectric power station. Photo 2 shows the crack location on a bar of the space-framed structure MARHI of the powerhouse hall at Sayano-Shushenskaya hydroelectric power station.

From presented photos it is seen that the longitudinal crack location on a bar coincides with location of SC lines detected by MMM.

The offered diagnostic method allows:

- to carry out an express control of load-carrying structures and to estimate their predisposition to damages;

- to estimate efficiency of different actions. At a control of load-carrying structures MMM allows to reveal stress concentration in local zones and in time to strengthen these zones.